|

Accessorizing:

Boating accessories are a weak spot of mine and the boat was a good excuse to pick up a few must haves. I started with the safety stuff: Fire extinguisher, spare kill switch lanyard, spare quart of oil, prop wrench, spare keys, trailer coupler lock, whistle, fuses, electrical tape, vice grips, tool kit, zip ties, floating keychain and wheel chocks. One of the trailer tie downs didn't ratchet correctly so I grabbed a new set of Boat Buckle tie downs and installed them.

On the fishing side of things I picked up a set of Ardent Smart Cull Buoys (phenomenal product), a dozen stick jackets, a Bends Mender needle, a dozen Plano 3700's, and a Save Phace mask. A lot of things I already had from my other boat like a throw cushion, life jackets, map chips, measuring board, balance beam, gloves etc. Isn't boating fun?

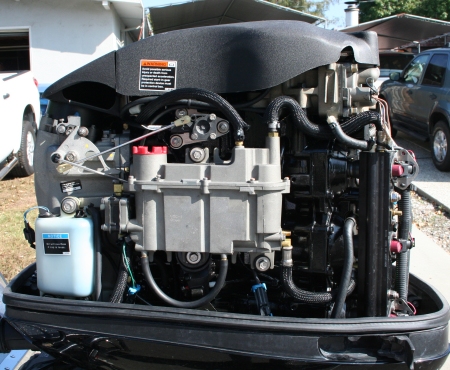

Engine Work:

The motor had 118 hours on it when I bought it and was up for a 100 hour service. John Lake offered to help me wrench on it so I picked up some parts and we pulled the cowling off to have a look-see. The lower unit service was no problem. The spark plugs were hard to get at and took some time. The cheap plastic cap on the fuel filter wasn't strong enough to get leverage on to remove it. We decided not to take off the lower unit and do the water impeller.

When we buttoned it up the engine ran horribly and died. We scratched our heads for a bit and came to the conclusion that I'd gotten the wrong spark plugs. After some back and forth with the shop where I bought them it turned out they were indeed the wrong plugs. They were the Optimax plugs, not the ProXS plugs. The lesson here is to give the shop your motor's serial number and make sure you get the right part. I wound up having the shop do the impeller, the fuel filter, and fix the plugs.

Wrong Spark Plugs

There were a few other minor things they fixed like putting a terminator on the Smart Craft gauge plug in (it was missing) and replacing a plastic cover on the side of the engine that was cracked. That was done under warranty. I learned that the shop has a special tool for removing stuck fuel filters. Good to know but not too helpful if you don't have the tool yourself.

Fuel filter With Red Cap - Hard to Get Off When Stuck

Boat Work:

The boat was pretty clean and didn't require any clean up externally. I waxed everything just for good measure. When I bought the boat, I knew that the livewell pump-out did not work so I tore apart the battery compartment, replaced the pump and cleaned everything up. The layout of the battery compartment on this boat is less than ideal. I'd go so far as to say that it is really annoying when you have large batteries that hang over the edge of the plate in the middle. Doing any kind of on the water work below the plate will be all but impossible.

Cracked Livewell Pump-out

On the way out I labeled all of the wires in the rear compartment with a simple system that will allow me to disconnect and reconnect everything without having to think about which wire is which. I discovered that the flasher and the console graph transducers were located right next to each other, which explained why the console graph would go haywire with the flasher turned on.

The boat has a Lowrance X-28c HD on the bow and a LMS 520 on the console. I put an old SD card from a camera in my old LCX-17 and pulled off all the way points, then transferred them to the new boat. A few tweaks on the graphs to turn the ping speed and the chart rate to 100% and they were ready to rock.

Trailer Work:

For some reason in the rush to get home I never thought to check the tire pressure. The tires looked a bit low and when I checked them they were all around 29 psi which was indeed low. These are Goodyear Marathons rated for 55 psi. I had a chat with several people about this topic and decided to go with 50 psi. There's a lot of opinions out there on tire pressure and you can form your own. 40 to 50 seemed to be the consensus I heard.

The trailer was the one area where I basically got burned on this purchase. Not being familiar with surge brake systems I didn't inspect it carefully. It turned out that on one side the brake line had snapped off at the caliper. This caused it to dump the brake fluid and rust out the caliper. Nico and I had noticed that the trailer felt jerky at starts and stops on the drive home, and I had added brake fluid when I got home. The level of the fluid stayed up because the line was rusted shut. This was a bit misleading and made it so I didn't find the problem sooner.

When I finally figured it all out and got it repaired (new caliper, repaired brake line, bleed the brakes) I drove home from the shop. On the drive home, now that there was pressure on the system, the other side went out. Several people had told me that Champion trailers have issues and I experienced it first hand with this rig. Could you imagine if a 2006 truck had brake lines that just snapped off at random? It would be on the front page of cnn.com. Boat trailers on the other hand seem to fall in to some other category where it's acceptable for important components to break after a few years of use. Disappointing.

The lesson here was to fully inspect the brake lines and calipers before buying the boat, and to hitch up the boat to the truck and drive it around to make sure the system works. I would not have known what normal driving felt like with the rig, so even then I may not have found the problem, but I would have seen the broken brake line if I had looked carefully. Lesson learned.

|